The Challenge

Customer contracted Utrex Limited to provide services for the inline blending of hydrochloric acid, hydrofluoric acid and inhibitors, subsequent dilution and delivery to down hole pumps and coil tubing unit (supplied by others) and thence to the re-injection well.

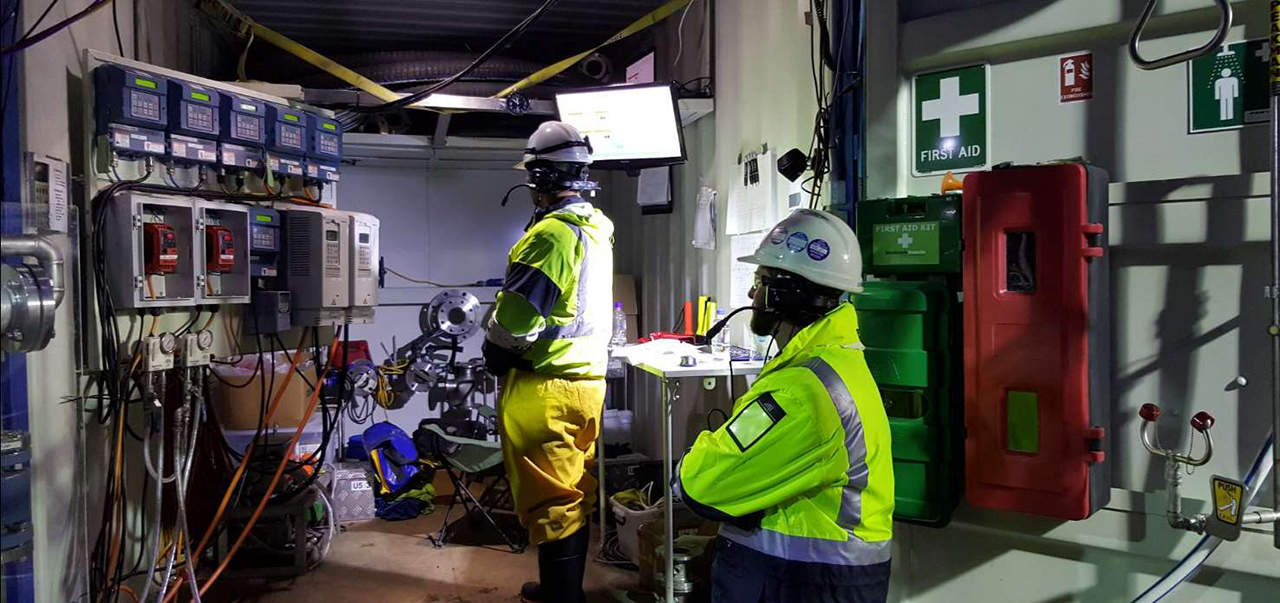

Fig 1. Utrex nightshift running inline blending manifold during injection

The Solution

Utrex Ltd provided services including staff, equipment and chemical, including:

- HSNO certified 70,000ltr 33% Hydrochloric Acid Storage

- Proprietary monitoring and blending container to mix and pump water, inhibitors, 33% Hydrochloric Acid, 70% Hydrofluoric Acid in a contained and continuous fashion. Including but not limited to pumps, flow meters, valves, manifolds and gauges.

- Supply of 20,000 L of 70% Hydrofluoric Acid, top loading/unloading ISO’tainer.

- Project management, supervisors, and technicians to facility the above.

Total program of approximately 615,000 litres of treatment fluid.

- HF 70% – 20,000 L (Utrex Supply)

- HCL 33% – 135,000 L (Customer Supply)

- Corrosion Inhibitor 1 – 3,936 L (Others Supply)

- Intensifier 1 – 3,747 L (Others Supply)

- Intensifier 2 – 1,874 L (Others Supply)

Chemical Regime

- Preflush: 10% Inhibited hydrochloric acid

- Main Shot: 10% hydrochloric / 5% hydrofluoric- inhibited

- Post Flush: 5% Inhibited hydrochloric acid

The overall project was a great success. In particular the ability of multiple groups and contractors working very closely to ensure the well stim chemicals were delivered as programmed to set locations in the well. The total volume of acid was delivered to the 6 zones in the well within 30 hours.

Fig 2. Plot during programme 10th May 2017